Mechanical Power Press is a useful sheet metal machine for bending, cutting, pressing, and shaping work pieces into various sizes and forms. It is typically utilised in metal fabrication companies and shops. This multi-tasking piece of equipment uses a press mechanism to compress and shape the appropriate material. The apparatus is capable of clamping the sheet of metal between its tools. Its basic frames are defined by its force or tonnage, as well as its working length. Power Press Machines are widely accessible in the market in both standard and customized configurations.

Mechanical power presses are devices that generate force and execute metalworking operations such as cutting, punching, and bending by utilizing mechanical energy. They are usually made composed of a motor, a flywheel, a clutch, and a ram that travels up and down to deliver force to the workpiece.

Power Capacity (Pr) | = | 45 Ton |

Stroke Length (St) | = | 100 mm |

Rated Distance | = | 3.974 mm |

Stroke per Minute | = | 75 SPM |

Rated distance | = | (1-cosα°)St/2 |

3.974 | = | (1-cosα°)50 |

α° | = | 23° |

Torque transmitted by the Crank Shaft in Mechanical Press | ||

Tc | = | Pr. sin23° |

= | 45 X 10³ × 50X10‾³ × sin23° | |

= | 879.14 Kg.m | |

= | 880 Kg.m | |

Tc (1.15%) | = | 1015 Kg.m |

Power Need for Electrical Motor in Mechanical Press | ||

P | = | E × (Stroke Per Min.) ÷ (60×0.8×0.8) |

= | (45 × 104 × 3.974 × 10‾³ × 75) ÷ (60 × 0.8 × 0.8) | |

= | 3492.77 Watt | |

P | = | 3.5 KW |

But it is standard motor is 3.7 kw = 5 HP | ||

Flywheel Rim Design Process and we are determining flywheel rim weight, flywheel width in Mechanical Press, Flywheel are used to store energy. We suppose that the size value is determined | ||

Rim OD | = | 590 mm |

Rim ID | = | 390 mm |

mean dia | = | 490 mm |

Flywheel Speed (N2) | = | 350 rpm |

Flywheel Speed (N2) | = | 332.5 rpm (Fluctuation 5%) |

Flywheel Energy (E ) | = | ½mv² |

Flywheel Velocity (v) | = | πDN÷60) |

E | = | 1015 Kg.m) above value |

E | = | ½m × [(πdN1 ÷60)² - (πdN2 ÷60)²] |

1015 | = | ½m × [(3.14×0.49×350÷60)² -(3.14×0.49×332.5 ÷60)² ] |

m | = | 256.9 Kg |

Now we can find out width and flywheel material is cast iron. | ||

Use a clutch in a mechanical press to control the power supplied from the flywheel shaft to the crank shaft in engaged and disengaged states. Right now, we're learning how to choose a clutch capacity in a mechanical press. | ||

Back shaft torque is | ||

Tb | = | Tc ÷ (Gear Ratio) |

Gear ratio | = | 4.66 (it is a ratio of crank shaft and back shaft ) |

Tb | = | 880÷4.66 |

= | 188.84 kg | |

Tb (1.15%) | = | 236 kg.m |

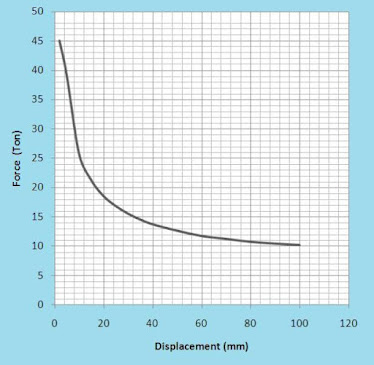

Mechanical Press Force Chart | ||

1 Comments